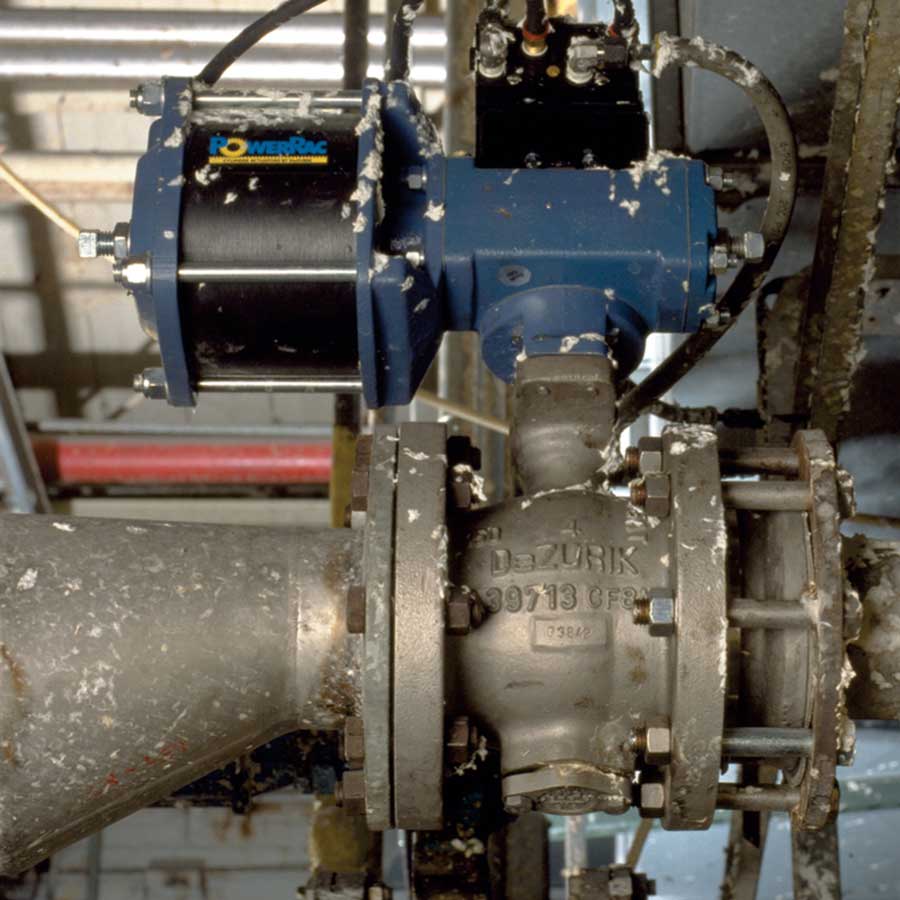

DeZURIK’s popular Power-Rac Actuated VPB V-Port Ball Control Valves are sized and calibrated for accurate control of paper stock, in addition to many pulp & paper clean, dirty, or corrosive liquids, and gases.

Providing Proven Pulp & Paper Brands Complemented by Experienced Valve Knowledge

TRIFLOW CORP brings leading brands of isolation and control valves and stainless actuators along with a proprietary direct steam injection systems from HydroThermal (HTC). HTC is a long-time performer in the bleaching process offering large energy savings by replacing inconsistent high maintenance and ‘old school’ traditional heat exchangers.

Some of our Pulp & Paper experience includes…