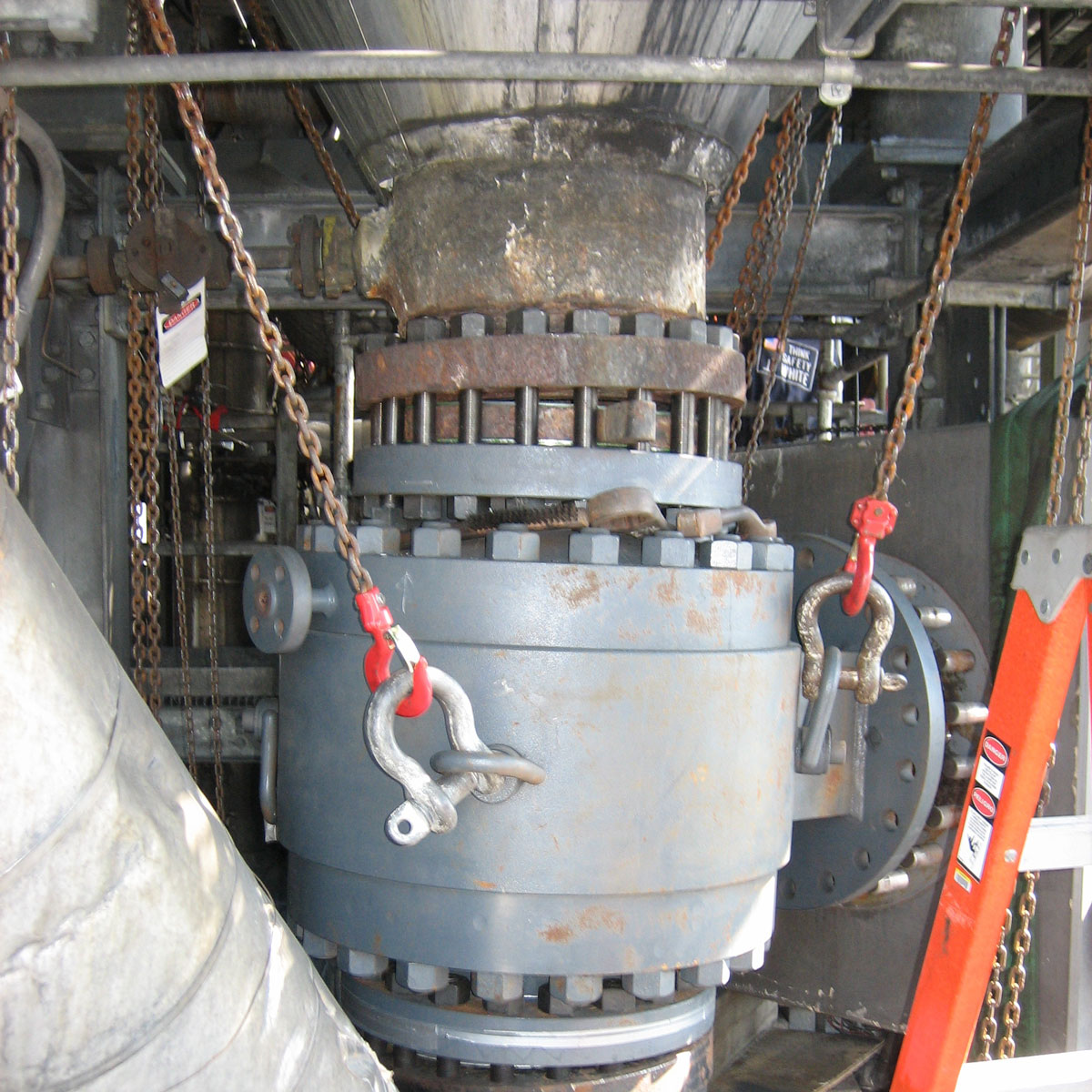

Gasification Lock-Hopper: lower hydraulic operated, high cycle, severe service class ball valve managing hopper discharge – every 15 to 30 minutes.

Process Exchange + Product Knowledge + Valve Types + Metallurgy = Our Experience

Breadth and depth of knowledge come from experience when selecting the right valve for your process applications. For over three decades TRIFLOW CORP has partnered with end users, EPCs, OEMs and licensors to exchange, challenge, and research the best solutions to ultimately improve operational efficiency and minimize downtime.

Some of our applications in the expanding world of Gases include…